Safety is Union Pacific's No. 1 priority. Nothing is more important than the well-being and security of our employees and the people who reside in the communities where we live and operate. Safe operations also are critical to meeting our customer commitments. We invest significant resources in training employees, developing innovative technologies and increasing railway safety awareness. Our ultimate goal is to achieve annual safety records on our way to zero incidents, building a safer America.

Operating Safely

Contains a script. Do not delete.

Operating Safely

Christian Lozano, manager-yard operations

Highlights, Challenges and Opportunities

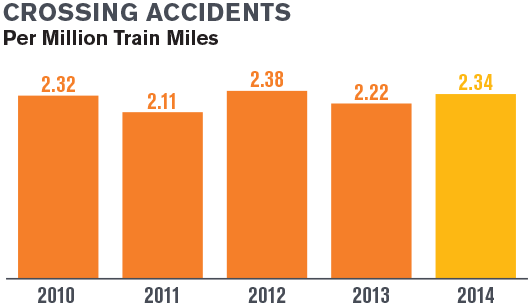

In 2014, Union Pacific made strides in operating safely and preventing accidents. Through our signature UP CARES public safety initiative, we continued a multi-media, bilingual public awareness campaign that educated drivers and pedestrians in various cities in Texas, Louisiana, Arkansas, California, Minnesota and Illinois about safety around railway crossings.

Union Pacific is on the cutting edge of developing technologies to improve railway safety. See this report's Technology in Safety section for examples. We believe that continued investment such as our $4.1 billion 2014 capital program and future expenditures give us the opportunity to cement our status as a leading innovator in this area.

Although derailments decreased by 7 percent from 2013 to 2014, achieving our goal of completely eliminating accidents on our railways will require further hard work.

Public Safety

UP CARES

Union Pacific's public safety program is UP CARES, the Union Pacific Crossing Accident Reduction Education and Safety initiative. Through UP CARES, we host events across our 23-state network to educate pedestrians, motorists and truck drivers about how to stay safe around railroads and grade crossings. In 2014, we held 13,580 events, reaching more than 629,500 members of the public.

UP CARES SAFETY GRANTS

UP CARES awarded grants ranging from $500 to $5,000, providing financial support for community-owned railroad safety initiatives in towns where Union Pacific operates. Organizations and programs receiving these grants included youth education activities, school or community safety days, community safety blitzes and grade crossing educational enforcement activities.

PUBLIC AWARENESS CAMPAIGN

In 2014, Union Pacific continued a multi-media, bilingual public safety campaign encouraging pedestrians and drivers to act safely at railroad crossings. As part of the UP CARES initiative, the public awareness campaign used radio spots and billboards in English and Spanish to reach audiences in Houston, San Antonio, Laredo, Midland and Odessa, Texas; Plaquemine, Louisiana; Little Rock, Arkansas; Fresno, California; Minneapolis/St. Paul, Minnesota; and Chicago.

Each radio spot featured a Union Pacific employee sharing a key railroad safety message:

- Drivers and pedestrians should cross railroad tracks only at designated crossings.

- Never use railroad tracks as a shortcut.

- If the railroad crossing gates are down, don't go around.

- When driving a commercial truck, know its vertical clearance to avoid getting high-centered.

- When approaching a railroad crossing, ensure there is enough space in front of your vehicle to completely clear the crossing.

UNION PACIFIC TAKES ACTION TO PROTECT SPORTS FANS IN SAN ANTONIO

Union Pacific partnered with the San Antonio Spurs to keep fans safe as they traveled to and from AT&T Stadium in June 2014 for the NBA Playoffs. After our train crews noticed cars were parked too close to the tracks near the stadium, we worked with the Spurs to arrange extra security on hand to ensure motorists parked a safe distance away. Union Pacific employees also staffed a rail safety booth at games, and the Spurs played an Association of American Railroads' public service announcement, encouraging fans to "See Tracks? Think Train."

"Spurs Sports and Entertainment is proud to partner with Union Pacific Railroad to ensure our fans enjoy the game atmosphere and stay vigilant around railroad tracks. We remind everyone that when you see tracks, always expect a train," said Bobby Perez, senior vice presidentcorporate relations and general counsel for Spurs Sports and Entertainment.

Employee Safety

Performance Overview

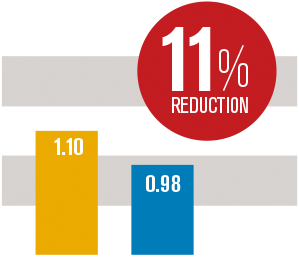

Union Pacific's 2014 annual employee safety performance was the best in company history. Employees lowered the reportable injury rate to 0.98 injuries per 200,000 employee hours – equivalent to 100 employees working a full year – breaking the previous record established in 2012. The 2014 rate represents an 11 percent reduction from the 2013 reportable rate of 1.10 and demonstrates our employees' dedication to reducing injuries and achieving the company's goal of zero injuries.

Courage To Care

In 2012, Union Pacific introduced the "Courage to Care" pledge. It represents a culture of safety and personal accountability and strengthens the degree to which each and every employee prioritizes safety as an issue. The pledge reads:

I have the courage to care. Worn with a lion's pride, it means those I work with will have my back, and I will have theirs. I pledge to shield myself and my team from harm. I will take action to keep them safe by fixing an unsafe situation, addressing an unsafe behavior or stopping the line. In turn, I will have the courage to accept the same actions from my coworkers, who care enough to correct my path. We wear this badge out of respect for each other and those who have gone before us. On my watch, we will all go home safe to our families every day.

Throughout the year, we conducted systemwide safety "stand down" meetings that focused on the role Courage to Care plays in employees' lives. Normal operations are suspended so in-depth safety conversations can take place. A meeting this fall included a video, "Courage to Care: On the Way to Zero," featuring employees in Los Angeles and El Centro, California, discussing the importance of identifying risk and returning home safely to their families.

Total Safety Culture

Total Safety Culture (TSC) is a voluntary employee-led initiative that teaches employees safe behaviors while providing observations and feedback. TSC directly empowers our union employees to address at-risk behaviors and receives the full backing of senior management.

Injuries per 200,000 employee hours

From left are Cameron Scott, Union Pacific executive vice president-operations, Huges and his wife, Nikki, and Lance Fritz, Union Pacific president and CEO.

Kenefick Safety Award Winner

John Hughes received the 2014 J.C. Kenefick Safety Award, Union Pacific's highest safety honor. Hughes was integral to the Houston Service Unit achieving a 40 percent reduction in human factor incidents.

He inspired co-workers on the Houston Service Unit through employee engagement and training programs, creating a cohesive family that holds safety above all else.

Hughes delivered more than a good safety strategy; he helped change the way people think about safety. As a result, the service unit returned more than 60,000 Total Safety Culture (TSC) observation cards.

His team also established "intensity rides," a process to identify risk and then apply TSC to help eliminate or mitigate it; developed goal setting cards for TSC participants; created a contest among teams and managers to see which group could complete the most TSC observations; taught TSC and job briefing classes to new hires, and helped design a new-hire safety training course.

Technology's Role in Employee Safety

Telematics

More than 2,650 company vehicles are outfitted with Telematics. This technology uses a telecommunications device to transmit real-time information about motorist behavior, including seat belt use, speed, and acceleration and deceleration, to provide feedback that informs safe driving habits. Reaffirming the practice of maintaining a steady safe speed, as opposed to rapid increases in speed or excessive braking, Telematics is among ongoing efforts to improve fuel economy.

In-Cab Cameras

We installed our first inward-facing cab cameras in 2014. By the end of 2016, we expect to equip 5,000 locomotives with this technology.

The inward-facing cameras join the locomotive fleet's external-facing cameras, called Track Image Recorders (TIR), that have been providing images of track, crossings and signals directly in front of locomotives since 2005. The video is used in conjunction with the locomotives' Event Recorder data, which includes train speed, throttle and brake settings, traction power levels and horn use.

Through the years, the TIR/Event Recorder data have validated the professionalism of train crews and the same results are expected from inward-facing cameras. Pro-active performance sampling of video can increase understanding of crew behaviors, so training and coaching can be improved.

Use of video technology to ensure safety, security and situational awareness is expanding in public places, government facilities and businesses. The rail industry reflects this worldwide trend, with cameras used in yardmaster towers, tunnels, shops, office buildings, crew vans, border locations and remote control locomotive (RCL) crossings.

Training Course for Experienced Drivers

For years, our Telecommunications employees have participated in a specialized course for experienced drivers that offers safety reminders and vehicle operating techniques. Based on related safety successes, this course is being deployed throughout our organization from senior leadership to all Operating Department employees who drive a company vehicle.

Security Personnel

We employ state-of-the-art, 24-hour security technology to detect unauthorized access. In conjunction with our own highly trained, commissioned police force, Union Pacific coordinates security efforts with U.S. Customs and Border Protection (CBP), the U.S. Coast Guard, the Federal Bureau of Investigation, the Central Intelligence Agency, the Department of Homeland Security, the Transportation Security Administration and local law enforcement. Union Pacific was the first U.S. railroad to be named a partner in the Customs-Trade Partnership Against Terrorism (C-TPAT), a CBP program designed to develop, enhance and maintain security processes throughout the global supply chain.

Hazardous Materials and Chemical Risk Reductions

We take seriously our responsibility to safely ship all freight. Our goal is the same as that of our customers and the communities in which we operate: for every car to be safely delivered, while being prepared to respond in the unlikely event of an accident.

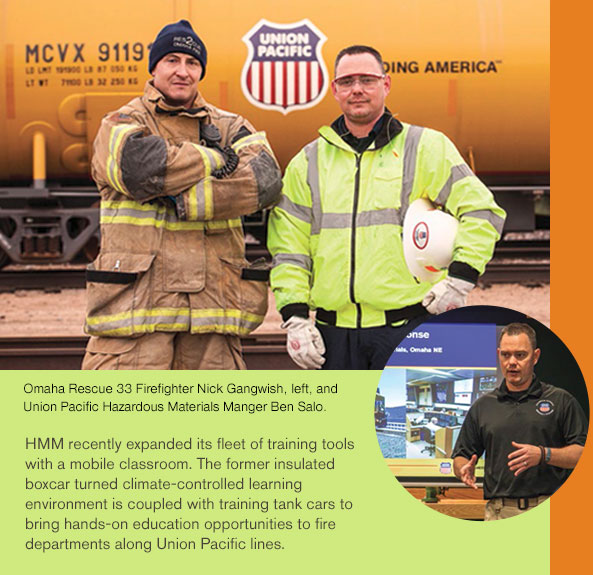

As part of our efforts to move freight safely, Union Pacific's Environmental Management Group includes a Hazardous Materials Management team (HMM). This group of experts is highly trained in hazardous material transportation safety, securement and response. Union Pacific has met stringent certification requirements under the American Chemistry Council's Responsible Care Management System (RCMS) program, demonstrating for the public and chemical customers our commitment to safely handling hazardous materials. The HMM team has a four-part mission: prevention, preparedness, response and recovery.

Prevention – Union Pacific's HMM managers regularly inspect tank cars moving on our network, conducting 6,000 customer tank car security and safety inspections annually. In each inspection, an HMM team member examines fittings, markings, safety appliances and waybills. HMM conducts tank car inspection blitz programs where Union Pacific managers, outside contractors, customers and regulators work together to inspect a large number of tank cars in a defined geographic area. We choose high-volume locations and perform around a dozen blitzes annually across the Union Pacific network.

Preparedness – Preparation is critical to responding appropriately to incidents. HMM developed the Union Pacific Hazardous Materials Emergency Response Plan (HMERP), a performance-based plan that provides guidance about reporting a release, as well as a list of training requirements for those responding to an incident. Each of Union Pacific's operating divisions undergoes an annual, unannounced drill to ensure all aspects of the HMERP are in place and are being followed by employees. Additionally, we offer no-cost training to public responders, including local fire departments, so they are able to effectively respond to incidents along the Union Pacific network should the need arise. HMM also performs large-scale training events in collaboration with Union Pacific's partners in TRANSCAER (Transportation Community Awareness and Emergency Response).

Response – When responding to any incident, it is important to follow a defined and carefully laid-out process. HMM's process is designed to be easily incorporated into the public response incident command structure. Union Pacific's Response Management Communication Center (RMCC) is an around-the-clock response center where dispatchers manage calls from the public, law enforcement and others who are reporting emergencies and other incidents on Union Pacific's 32,000-mile network. RMCC follows all regulations regarding notification of local, state and federal agencies about accidents, and the company works closely with first responders throughout an incident.

Recovery – Once an incident has been stabilized, recovery begins. If a tank car has been damaged and cannot travel safely on the railroad, the contents must be transferred to an undamaged car. Union Pacific owns and operates all equipment necessary to transfer any liquid or compressed gas from one tank car to another. After a tank car becomes liquid free, HMM purges and cleans the damaged car to ensure it can be safely repaired or dismantled. Once all hazardous materials have been removed from the incident site, HMM transitions the project to the Union Pacific Site Remediation group for remediation and closure with regulatory agencies. The final steps of recovery include a debriefing with the public responders and an internal post-incident analysis. These activities are an invaluable means of augmenting the group's overall capability to respond to a hazmat-related incident.

Crude by Rail

We understand the risks associated with crude-by-rail are a real concern and take our responsibility to ship crude oil, as mandated by federal law, seriously. We follow strict safety practices, and in many cases, exceed federal safety regulations.

Union Pacific works collaboratively with other railroads, customers and the U.S. Department of Transportation to maximize crude-by-rail safety without compromising operational efficiencies necessary to make America run smoothly. This extended to participating in the railroad industry's crude-by-rail voluntary safety operating practices announced Feb. 21, 2014, by U.S. Transportation Secretary Anthony Foxx. These voluntary safety measures included train speed slowdowns through Department of Homeland Security-designated High Threat Urban Areas, increased track inspections, enhanced braking systems, expanded use of rail traffic routing technology to include crude oil, intensified community relations programs, and stepped-up emergency response capability planning and training.

In 2014, Union Pacific joined other railroads to help first responders with community-specific education needs, contributing $5 million to develop a specialized, comprehensive crude-by-rail training and tuition assistance program.

In 2015, the Federal Railroad Administration (FRA) issued an Emergency Order and Safety Advisories addressing operating practices affecting high hazardous flammable materials transport. The issuances were followed by tank car regulations released by the Department of Transportation (DOT). Union Pacific fully supports efforts to make the rail system even safer. The DOT rules are a step in the right direction, but some of the changes will have far-reaching negative consequences for the railroads, our customers and the broader economy. For instance, Union Pacific believes electronically controlled pneumatic (ECP) brakes do not provide significantly greater safety benefits than distributed power, especially on the terrain through which our trains operate. For updates, visit our Crude by Rail Web page.

AskRail Response Tool

Union Pacific is introducing first responders on our rail network to AskRail,™ a near-real-time mobile application produced by the Association of American Railroads (AAR).

Union Pacific's Hazardous Materials Management (HMM) team members work with local emergency responders along Union Pacific rail lines to grant access to the AskRail app. Once first responders have downloaded the AskRail app onto their mobile device, they can enter the identification number located on a tank car to identify the car's contents. AskRail supplements the existing response process Union Pacific's HMM group uses to collaborate and communicate with emergency responders during a hazardous materials-related incident.

Issue in Focus: Derailment Prevention

At Union Pacific, we take our responsibility for safe, reliable, efficient service seriously, and that means using all tools at our disposal to prevent derailments.

Employees engaged in continuous improvement, risk identification and mitigation, work standardization, variability elimination, Total Safety Culture and other initiatives are identifying the root causes of derailments, addressing potential risk, proposing solutions and consistently enhancing processes to improve safety and service. As a result of these efforts and our innovative technological solutions, these incidents are becoming increasingly rare. Derailments decreased by 7 percent from 2013 to 2014, from 3.24 reportable derailment incidents per million train miles to 3.00, and by 38 percent over the last 10 years. Our goal is to have zero derailments.

Some of the specific ways that Union Pacific and our employees are reducing derailments include:

Houston Reduces Human-Factor Incidents

Geometry Cars

Wind Monitoring Devices

High-Definition, High-Speed Imaging Systems

Houston, You Solved a Problem

Houston-area employees are creating solutions through teamwork. The local Derailment Prevention Team presented its best safety practices at the Association of American Railroads Leadership Forum. Through use of the 8-step Problem Solving Process, months of observation, countless hours of interpreting feedback and analyzing data, team members identified the top three causes of human-factor derailments at their location and developed initiatives to target each. The result was a reduction of more than 50 percent in the monthly average of human-factor incidents.

Geometry Cars

In addition to relying on employees' expertise, Union Pacific deploys cutting-edge technological solutions to help prevent derailments. Two 105-ton geometry cars travel an estimated 70,000 miles of rail annually to check the rail's gauge, alignment, profile, cross-level, elevation, curvature, curve speed, harmonics and warp. These cars also check rail wear and clearance, as well as ballast measurements. These tests help predict where derailments may be more likely to occur, so that preventive maintenance can be conducted.

Wind Monitoring Devices

Wind monitoring devices reduce the risk of high winds blowing over trains, notifying us immediately when wind speed reaches certain thresholds so we can take preventive action.

Machine Vision Imaging System

Currently in test phases, these cameras take images of railroad cars traveling along our tracks. The technology allows out-of-tolerance conditions and deviations to be detected and further reviewed.

Key Awards and Recognition

- National TRANSCAER Award Recipients Recognized for Improving Safety of Transporting Hazardous Materials*

- Union Pacific Railroad Police Receive CALEA Accreditation

*Awarded in 2014 for 2013 performance.